Techno-economic assessment of coupling direct air capture with formic acid value chain in buildings under different scenarios

This week, we deep dive into a paper recently published in Energy Conversion and Management. The study was conducted by Youssef Elaouzy, affiliated with the Applied Chemistry & Engineering Research Center of Excellence of the University Mohammed VI Polytechnic in Ben Guerir (Morocco).

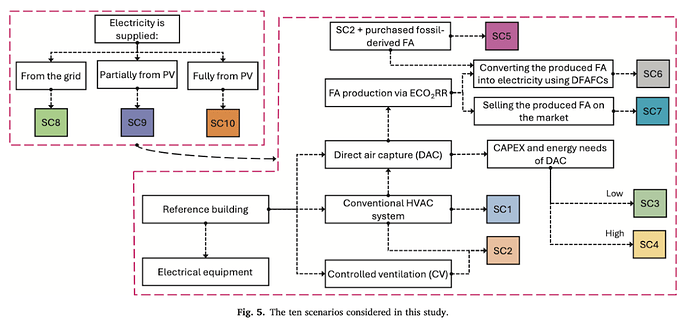

This study evaluates a novel carbon capture and utilization (CCU) pathway that combines direct air capture (DAC) of indoor CO₂ with its electrochemical conversion to formic acid (FA) and optional use in formic acid fuel cells (DFAFCs) within building environments. It assesses energy performance and economic feasibility across ten scenarios, factoring in ventilation methods, costs, carbon tax, and market conditions. Results highlight that while DAC can improve indoor air quality, it requires more energy than traditional ventilation systems, and the electrochemical conversion step is the most expensive stage, as converting FA back into electricity isn’t always cost-competitive.

By integrating a full carbon capture and utilization chain directly into building systems, this study moves beyond typical DAC applications focused solely on air quality or emissions reduction. While prior studies have examined DAC integration with HVAC systems for indoor air quality improvements or separate evaluation of CO₂ capture and utilization technologies, few have combined the full cycle from CO₂ capture to chemical conversion and potential energy re-use within the same built environment. This study bridges indoor air quality enhancement with a CCU value chain that produces a marketable chemical (formic acid) and explores its dual role as both a commercial product and an energy carrier via DFAFCs.

Key findings reveal that although incorporating DAC into building environments can significantly reduce indoor CO₂ concentrations, its energy requirements are 21–27% higher than conventional controlled ventilation systems, resulting in substantial costs per tonne of CO₂ captured (typical levelized costs range from $56 to $259 per ton depending on scenarios). Among all segments of the CCU chain, the electrochemical CO₂ reduction to formic acid (ECO₂RR) is the most cost-intensive element, with FA production costs between approximately $1.01 and $1.26 per kilogram. If formic acid is then used to generate electricity via direct formic acid fuel cells, the resulting cost of electricity (LCOE) lies between about $1.38 and $2.10 per kilowatt-hour — a rate that currently challenges competitiveness against typical grid or renewable electricity prices. Importantly, the authors point out that economic viability improves under favorable conditions — particularly when supported by renewable energy sources, carbon tax incentives, or market premiums for low-carbon chemicals — offering practical thresholds for investors, urban planners, and policymakers considering CCU deployment in built environments.

Here is a list of the main takeaways of this paper:

- The paper assesses a complete indoor carbon capture and utilization chain converting captured CO₂ into formic acid and optional energy use, offering a novel building-centered CCU framework.

- Direct air capture of indoor CO₂ requires more energy than conventional controlled ventilation, making its baseline operation energetically and economically challenging.

- The electrochemical step converting CO₂ to formic acid is the most expensive part of the value chain, dominating overall cost outcomes.

- Using formic acid to generate electricity via DFAFCs currently yields high levelized energy costs, reducing competitiveness under many scenarios.

- Economic viability improves under renewables integration, carbon pricing, and favorable market conditions, offering guidance for future investments and policy design.

Read the full paper here: Techno-economic assessment of coupling direct air capture with formic acid value chain in buildings under different scenarios